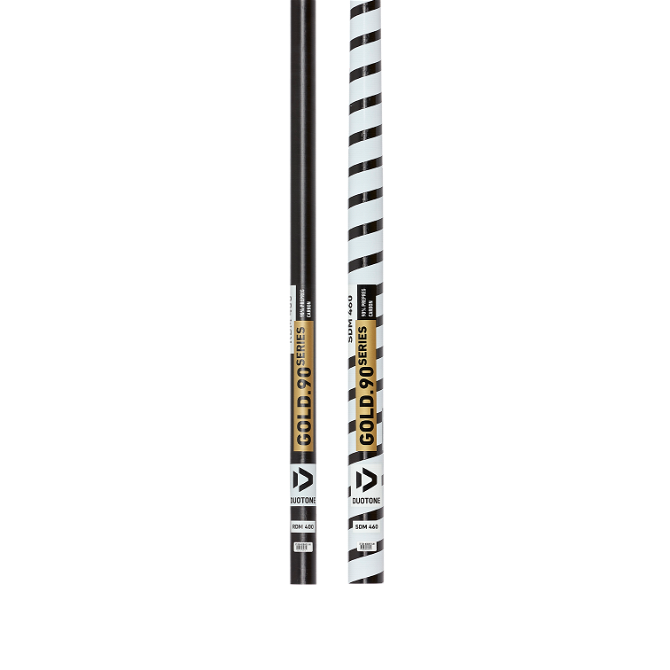

Gold.90 Series

THE HIGH END MAST RANGE NOW WITH 90% CARBON

Gold.90 Series

More carbon, better performance, higher load reserves! Made from 90% high-tech T800 carbon, the GOLD.90 is manufactured to the state-of-the-art prepreg design and, apart from the slightly lower carbon content, is technologically identical to the PLATINUM. The excellent dynamics and balanced bend curve make the GOLD.90 the most lightweight and highest performing mast in its class. As the more affordable version of the PLATINUM, it is a high-end mast for all ranges of use which is very light and yet astonishingly durable. And on that you have our word – backed up by an unlimited two-year warranty.*

WANNA MAKE IT UNCONDITIONAL?

THIS PRODUCT IS QUALIFIED FOR A 2 YEAR UNCONDITIONAL WARRANTY. TO SECURE THE EXTENDED CLAIMS PLEASE REGISTER WITHIN 30 DAYS.

OTHERWISE JUST THE LEGAL WARRANTY PERIOD CAN BE GRANTED!

PLEASE REGISTER HERE

Reviews

KNOWLEDGE BASE MASTS

UNIQUE FEATURES - WANNA KNOW WHAT'S SPECIAL ABOUT DUOTONE MASTS?

DUOTONE SENTEX® masts are extremely light, incredibly balanced and are far superior to other masts in terms of handling and reflexes. Thanks to the revolutionary SENTEX® material structure, they are also phenomenally durable and resistant to stress, which is why SENTEX® is also used for the PLATINUM booms.

WHAT’S THE SECRET?

SENTEX® is a highly developed composite material used exclusively by DUOTONE. It contains the highest-quality Toray resins which, in combination with the carbon fibres, achieves unique durability while keeping weight to a minimum. SENTEX® masts and booms are light as a feather in your hands and are far less liable to being broken. In addition, the masts have an outstanding level of reflex and the booms are extremely stiff.

THE MATERIAL

SENTEX® is made from the highest-quality carbon fibres and resin impregnated with silicon nanospheres. This technology produces a unique material structure which is more stable and noticeably lighter than regular carbon. The key reasons for this are the two advantages of silicon nanospheres:

The even distribution of nanospheres in the resin creates an extremely balanced rigidity across the entire mast length and ensures incredibly immediate and balanced reflexes.

Silicon nanospheres deal with compression force better than any other material known. This makes our SENTEX® masts and booms at least 30 % more resilient and durable than standard carbon products.

Because SENTEX® is far more stable, not as much material is normally needed, which is why the products are lighter than similar models. More specifically, this means a weight saving of up to 20 %, which is exactly why all DUOTONE PLATINUM booms and RDM masts are the most lightweight in their class worldwide.

THE essential quality criterion of carbon fibers when used for Windsurf masts is the bending-elongation of the fiber. The elongation measures the traction during bending until the fiber finally breaks. Carbon fibers are available with bending-elongation values between T300 and up to max T1000 with the T1000 carbon being 10-times as expensive as cheap T300 carbon. The lowest quality carbon fibers used on Windsurf masts have an elongation value of T300-400. This carbon has a bending-elongation that is just slightly higher than glass fiber. Therefore it’s used on cheap “low-percentage carbon masts” only.

For a Windsurf mast this means:

The higher the bending-elongation value of the carbon fiber raw material

→ The faster the reflex speed (which ultimately increases the performance of your sail, similar to increased horse power in a car)

→ The higher the breakage strength

Most brands nowadays use T400-500 for their top-level carbon masts. At DUOTONE we use T600 carbon for all BLACK masts, T700 for all SILVER and GOLD masts, T800 for all PLATINUM SLS masts and T900 for the PLATINUM Aero 3.0 masts.

Another advantage of the high quality carbon fibers is that you can reduce the resin content. For example the T900 fiber used for the PLATINUM Aero 3.0 mast allows us to reduce the resin content by 30%. This results in the lightest mast on earth.

MAST BASICS - THE MOST UNDERRATED PART OF YOUR RIG

The importance of the mast is usually extremely underrated. In fact, the mast is comparable to the transmission of a car. Or in other words, a Ferrari with only one gear is not very fast, only the correct transmission maximizes the potential of the engine into v-max.

When you compress a mast using downhaul tension every mast has a specific bend curve. This bend curve has to match with the luff curve of your sail in order to work in conjunction with the sail. On the other hand if the mast has a different bend curve than the luff curve both parts work against each other. Therefore it is utmost important to buy the right mast for your sail.

To say it load and clear: a wrong mast will destroy min. 30% of your sails performance or in other words will turn a winner into a shit sail!

The only other thing you can do to kill your sails performance is wrong/insufficient downhaul tension.

At DUOTONE we use a Medium Constant Curve for our masts (our bend percentages range between 61-63 bottom and 75-77 top depending on model and length). As this curve sits right in the middle within Constant Curve masts it offers the biggest compatibility of any bend curve. This makes our masts and sails the most compatible on the market.

HERE IS HOW GOOD OTHER BRAND SAILS WORK WITH OUR MASTS AND VICE VERSA:

Challenger Sails, Ezzy, GA (2017 on), Goya, Gun Sails, KA Sails, Loft Sails, Naish Sails, NeilPryde (RDM masts), RRD, S2Maui, Sailloft, Sailworks, Severne (RDM masts, 2014 on)

>> 80-90% (depending on model and size)

Hot Sails, NeilPryde (SDM masts), Point7, Severne (SDM masts, 2014 on), Simmer Style

>> 70-80% (depending on model and size)

Avanti, Gaastra (until 2016), Maui Sails, Severne (until 2013), Vandal

>> Not compatible

In general, at Duotone, we modify our mast curves just very, very moderately, if at all, from one year to the next. There are 2 reasons for this:

1. we try to keep our masts compatible with our sails for as long as possible to avoid forcing customers to always buy a new mast with their new sail.

2. our sail designer Kai is always trying to reduce the "design variables" as much as possible. This way he can constantly improve the sails performance. And since the mast curves have a tremendous impact on the sail, he is not very eager to change the curves.

Even on our high-performance Platinum mast series, the bend curves are only slightly adjusted from year to year. All other mast series generally remain completely unchanged. This means that as long as you are not a Word Cup pro, you can use 10 year old or even older Duotone masts (or from our previous brand) in our sails.

1. MAST STIFFNESS

Your rig is like a bird's wing, it is not a static but a dynamic object. Everything above your boom is under permanent movement to react/adapt to changing wind conditions (wind strength and direction) as well as to water movement.

There is a simple rule across all masts: the longer the mast the stiffer it is, or rather, the stiffer it must be. This is simply because the larger the sail surface becomes, the more support it needs from the mast. In a way the mast is the backbone of your rig.

What happens if a mast is too stiff or too soft for the sail (size)?

1. mast too stiff: the rig becomes super hard to control (especially when powered up) and uncomfortable (exhausting) to sail as the mast doesn't flex sufficiently e.g. when a gust hits your sail.

2. mast too soft: a mast that is too soft reduces the profile in the sail (because it already bends too much when downhauling the sail). When sailing It also bends too much with every gust. Both factors reduce the performance of your sail.

Your body weight also plays a role here. On the same sail a 60 kg lightweight will want to use a slightly softer mast than a 90 kg heavyweight sailor.

2. MAST DIAMETER (RDM VS. SDM)

There are two diameters existing:

1. SDM (Standard Diameter Mast) with 48,5 mm inside diameter at the bottom

2. RDM (Reduced Diameter Mast) with 32-33 mm inside diameter at the bottom

RDM masts make sense only up to lengths of around 430 cm, as they have a rather soft flex behaviour due to their smaller cross section. Therefore, they are primarily suitable for Wave/Freestyle sails with the additional advantage that they are easier to grip during manoeuvres.

On the other hand, larger, mostly performance-oriented sails require stiffer masts with a “more direct“ flex. This characteristic requires a larger mast cross section in order to achieve the required stiffness.

3. CARBON CONTENT >< WEIGHT >< PRICE >< PERFORMANCE

Compared to glass fiber, carbon is

a much stiffer fiber:

Due to this higher stiffness, less material/wall-thickness is requires, which ultimately results in a much lighter mast. The weight of the mast has an significant influence on how light the whole rig feels in your hands. No joke compared to a 50% carbon mast with a 100% carbon mast your rig will feel as if it would be 1 square meter smaller! And this is something everyone from beginner to World Cup pro will immediately feel and appreciate.

a much faster reacting (responsing) fiber:

When a gust hits your rig it twists off to absorb the sudden energy surge (instead of pulling you into a catapult). In order to create forward movement the mast has to reflex back. The faster this happens the faster the rig is ready for the next gust/impact.

a much more expensive fiber:

Unfortunately carbon fiber is 10-20 times more expensive than glass. That means the higher the carbon content, the more expensive the mast.

Due to the production process, bases and tops have certain tolerances in diameter and are therefore individually adjusted for fitting accuracy during production. Therefore, we can unfortunately not offer these products as spare parts.

Point loading is the first enemy of the mast

Always protect your mast from impact damage or point loading. Carbon is very vulnerable to impact damage. Even if there is no visible damage, the mast may be seriously damaged if it is dropped or knocked, which will, when put under load, result in breaking. For storage, transportation or simply whenever not being used, ALWAYS store your mast in a protective mast bag.

Sand is the second enemy of the mast

Before rigging up please make sure that all your rig components (mast extension, mast top and base, mast sleeve, cambers, boom front-end) are absolutely free from sand and grit.

If you don't want to end up with a one-piece mast (no joke) please always make sure not to have any sand inside the top part or on the connection joint of the base when putting both parts together. If you want to be on the safe side secure the gap between the base and the top using tape.

Permanent downhaul tension is the third enemy of the mast

In order to generate maximum performance your mast should be straight when not under tension. However, due to the massive downhaul tension, over time eventually every mast will take a bit of pre-bend. Once this happens it will only get worse as the mast automatically twists into its pre-bend position when downhauling the sail. The only thing that keeps your mast straight for as long as possible is to release the tension while not in use. This means that you should never leave your sail under full downhaul tension overnight.

That's also the reason why bending is excluded from our unconditional warranty.

WE DO CARE

Sustainability is the most important and pressing challenge of todays mankind to secure a livable mother earth for future generations to come!

Over the last 50 years Windsurfing has developed into a super high tech sport. But let's face it despite what others might tell you with the exception of aluminium booms and extensions Windsurfing products are a "mixture of petrol-based plastic trash". And most times up to 100% of this plastic trash are non-recycled (means "freshly produced") plastics.

At least as of today there are no eco-friendly substitutes existing offering the minimum requirements necessary to design modern Windsurfing products. Or why do you think no one wants to sail with wooden booms, aluminium masts or stretchy sails made of woven fabrics anymore?

There is only one sustainable way out of this dilemma:

MAKING LONGER LASTING PRODUCTS (LONGEVITY = SUSTAINABILITY)

A high performance product that lasts longer and best case can even be put into additional use on the second hand market is the best and only way to conserve the resources of our earth.

Of course light components have a massive impact on the performance and handling of your rig. That's why light weight is always on our briefing list when designing and engineering new products. And DUOTONE products are among or in many cases are the lightest on the market.

But durability and longevity were and will ALWAYS be on top of our priority list. Our industry leading warranty extensions bear witness to this philosophy:

- 2 year unconditional warranty on almost every hardware product (masts, booms and extensions+bases).

- 5 year warranty on 80% of our sails.

On sails we cannot emphasize enough that especially reducing the thickness of the monofilm and the XPly laminate has a radical influence on the longevity/sustainability. Reducing the film thickness by 50% reduces the UV-stability by 70%. Just to shortterm impress magazine testers or customers some brands use up to 70% thinner laminates/films than we do. This is not our understanding of sustainability.

DOING MORE

However, since we are fully aware of the importance of sustainability, we cannot simply stop here.

>> Only we have stopped using any plastic for packaging our sails. This saves approx. 5 sqm of plastic film and foam per sail.

>> Only our aluminium products (booms and extensions+bases) are manufactured in a CO2 neutral production facility.

>> Only our aluminium products (booms and extensions+bases) are produced in Germany using 100% European raw materials in order to keep shipping distances (to our manufacture and then to our central warehouse) at a minimum.

>> Only our sail bags are made out of 100% recycled plastic.

>> Only we compensate all carbon emissions caused by our sails during manufacture and transport by supporting a hydropower carbon offset project in Sri Lanka, the country where our sails are produced.

WE DO LISTEN - BECOME PART OF THE DUOTONE DEVELOPMENT

DO YOU HAVE ANY INPUT OR IDEAS ON HOW TO IMPROVE OUR PRODUCTS?

SHARE YOUR THOUGHTS WITH US!

We strive to create products that are superior in performance and function to anything else on the market. Therefore, we are not just interested in the opinion and experience of professional riders, but listen to ALL windsurfers out there. Because we know we can learn from everyone, we want to collect the opinions of windsurfers worldwide.

This project runs throughout the whole year. Every year on January 15th, the best ideas will be rewarded and might actually be implemented into future products.

So, you have got an idea? Contact us >HERE< and take your chance to make a difference. (Please use "R&D input for DTW" as a subject line)

REWARDS

1st - One sail (free of choice)

2nd - One Silver Boom (free of choice)

3rd - One Power.XT 2.0 (free of choice)

Any comments or questions? Here you’ll find first hand R&D / rider Information.

The more info you provide, the more specific the advice/help will be. Please let us know:

Your skill level

Your body weight and size

Mast(s) you plan on using with the sail

Board(s) you are using

Conditions/spots you are sailing at

Please note: To help as many people as possible follow the thread, the forum language is English only.

:grayscale(false):quality(10):blur(20))

:grayscale(false):quality(10):blur(20))