Item-no. 14220-7303

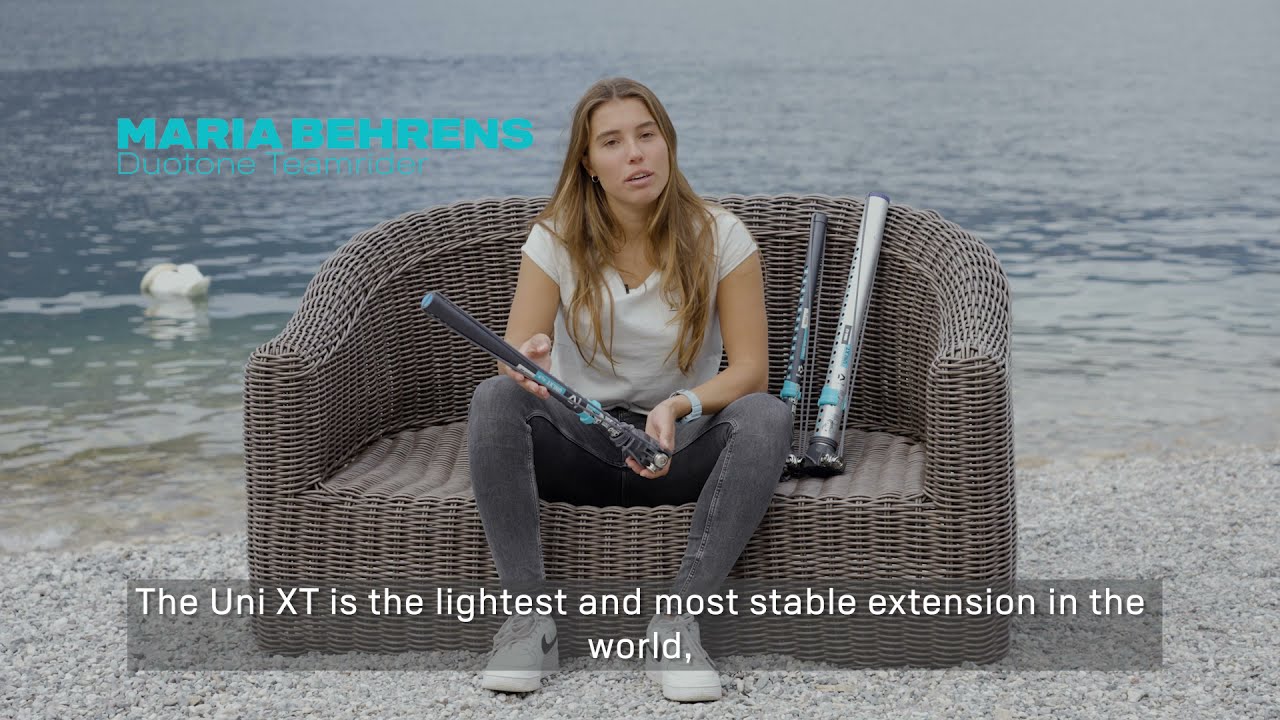

An inspiring (r)evolution – the POWER.XT 2.0 can do much more and do it better than the previous model. And as POWER.XT 2.0 SLS RDM 36 it is also the most lightweight ratchet extension of all time!

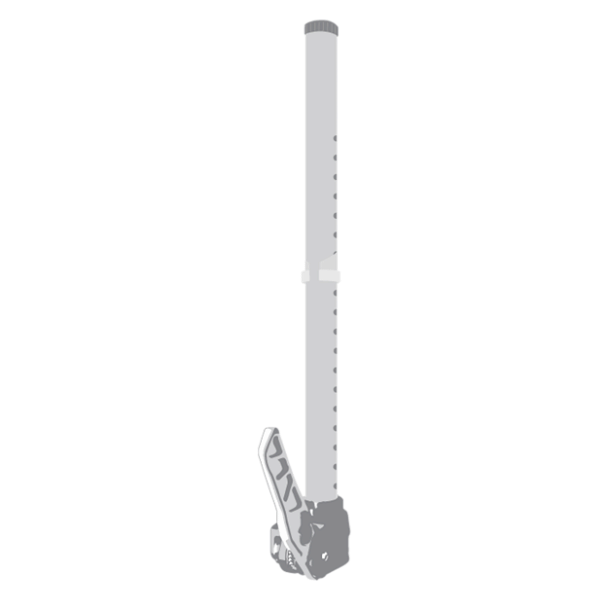

Beyond the basic idea, the POWER.XT 2.0 has almost nothing in common with the previous model any more. From the extremely solid ratchet mechanism plus lever to the simplified release mechanism, the high-strength Lyros® Dyneema harness downhaul lines and the option to retrofit the damper function – everything has been radically upgraded. The latest version comes with a completely new adjustment ring, which offers a unique feature: based on the tried-and-tested SDM adjustment ring, the RDM version now for the first time ensures that the aluminum tube does not come into contact with the mast anymore, which avoids any contact corrosion. No other RDM extension can offer that! In order to guarantee the same durability despite the reduced diameter, a double-walled sandwich construction of 7075 aluminum outer tube and ovalized T8 inner tube is used (patent pending).

For many years, the POWER.XT has been the benchmark when it comes to extensions with trimming tools. Those who use it will never want to do without it again. Thanks to the integrated lever, it overcomes even the strongest downhaul forces, enabling perfect re-trimming or fine-tuning even when on the water. Even children could handle the extreme luff tension of modern slalom sails, each profile can be adjusted to millimetre precision in a matter of seconds. The 15 cm long lever and the ratio of 1:60 enable trimming without any noticeable effort.

Beyond the basic idea, the POWER.XT 2.0 has almost nothing in common with the previous model any more. From the extremely solid ratchet mechanism plus lever to the simplified release mechanism, the high-strength Lyros® Dyneema harness downhaul lines and the option to retrofit the damper function – everything has been radically upgraded. The latest version comes with a completely new adjustment ring, which offers a unique feature: based on the tried-and-tested SDM adjustment ring, the RDM version now for the first time ensures that the aluminum tube does not come into contact with the mast anymore, which avoids any contact corrosion. No other RDM extension can offer that! In order to guarantee the same durability despite the reduced diameter, a double-walled sandwich construction of 7075 aluminum outer tube and ovalized T8 inner tube is used (patent pending).

For many years, the POWER.XT has been the benchmark when it comes to extensions with trimming tools. Those who use it will never want to do without it again. Thanks to the integrated lever, it overcomes even the strongest downhaul forces, enabling perfect re-trimming or fine-tuning even when on the water. Even children could handle the extreme luff tension of modern slalom sails, each profile can be adjusted to millimetre precision in a matter of seconds. The 15 cm long lever and the ratio of 1:60 enable trimming without any noticeable effort.

RATCHET SYSTEM

The only extension featuring an INTEGRATED RATCHET SYSTEM (patented)

2 THREAD SYSTEM

Compatible with all sail brands

RAPID RELEASE

Instant De-rigging

DYNEEMA ROPE

Original LIROS® Dyneema Rope

2 YEAR UNCONDITIONAL WARRANTY

Two years unconditional warranty when registered online

iSNAP 2.0

The lightest and most intuitive length adjustment system todate!

MODEL

EXTENSION RANGE (cm)

TUBE MATERIAL

WEIGHT (G)

UPGRADE INTO SHOX

Reviews

Any comments or questions? Here you’ll find first hand R&D / rider Information.

The more info you provide, the more specific the advice/help will be. Please let us know:

Your skill level

Your body weight and size

Mast(s) you plan on using with the sail

Board(s) you are using

Conditions/spots you are sailing at

Please note: To help as many people as possible follow the thread, the forum language is English only.

:grayscale(false):quality(10):blur(20))