Platinum Series AERO 3.0 2024

DER LEICHTESTE UND EXKLUSIVSTE GABELBAUM DER WELT

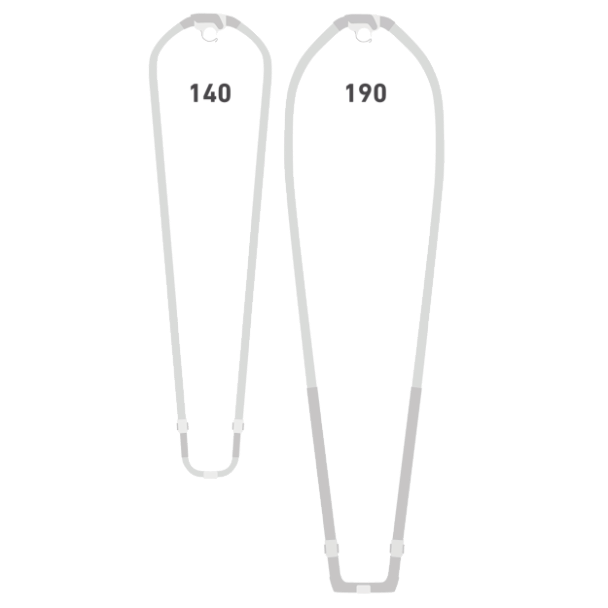

GIB ES ZU, DU WILLST SIE HABEN: PLATINUM AERO 3.0 IST DIE LEICHTESTE GABEL DER WELT (140-180: 1,65 KG | 190-250: 2,85 KG!) UND DAS NONPLUSULTRA IN PUNCTO TECHNOLOGIE, GEWICHT UND VERARBEITUNG.

Allerdings wird es aufgrund der unglaublich aufwendigen Fertigung nur eine extrem limitierte Anzahl geben (first come first serve). Dank hochwertigstem Materialmix und einzigartiger Produktionsweise ist sie sagenhafte 250-400g leichter als das ohnehin sehr leichte PLATINUM SLS Pendant. Trotz "Magersucht" überzeugt die PLATINUM AERO 3.0 mit sensationeller Steifigkeit, ultra direktem Feeling und einsatzspezifischen Features und Biegekurven, die sie zum "must have" für Hochleistungspiloten machen. Auch wenn die AERO 3.0 nur in zwei Längen angeboten wird, besitzt sie alle Leistungs- und Ausstattungsmerkmale der PLATINUM SLS Gabel (siehe unten). Eine Warnung müssen wir aber aussprechen: High End Technologie hat ihren Preis, also nicht erschrecken. NEU: die 140-180 Mega Slim verfügt über den brandneuen VTS TAIL Beschlag. In Kombination mit den 2022er Duotone Segeln bietet der VTS TAIL Beschlag erstmals eine klare optische Anzeige für die perfekte Schothornspannung (Patent angemeldet).

Bewertungen

WISSENSGRUNDLAGEN GABELN

DUOTONE CARBON BOOM TECHNOLOGY - THINK DIFFERENT

Es gibt 2 Herausforderungen denen sich jede Windsurfing Gabel stellen muss:

Fakt #1: je länger die Gabel und je kleiner der Durchmesser, desto weicher wird sie

Fakt #2: je kleiner der Durchmesser (im Griffbereich), desto höher der Griffkomfort und desto geringer die Ermüdung (= längere Sessions auf dem Wasser und/oder mehr Power für das Rennen)

Unser Ziel war es, eine Gabel zu entwickeln, die maximalen Griffkomfort (durch einen möglichst dünnen Griffdurchmesser) mit maximaler Steifigkeit kombiniert - normalerweise zwei Dinge, die nicht miteinander kombiniert werden können, da sie gegeneinander arbeiten.

Mit der längsten Erfahrung der Branche in der Entwicklung von Windsurfing-Gabeln haben wir nach 3 Jahren unermüdlicher Entwicklungsarbeit eine innovative Lösung gefunden: SEGMENTED CROSS-SECTION TECHNOLOGY

Anstelle des üblichen runden Querschnitts verfügt die neue PLATINUM SLS Gabel über 3 verschiedene Querschnitte, die jeweils individuelle, auf den jeweiligen Abschnitt der Gabel zugeschnittene Aufgaben erfüllen::

VORDERER BEREICH

Der Frontbereich, insbesondere im Bereich neben dem Kopfstück, ist für ca. 30-40% der gesamten Gabelsteifigkeit verantwortlich. Die Kräfte wirken in mehrere Richtungen durch den seitlichen Zug der Hände und die nach unten gerichteten Kräfte des Körpergewichts. Deshalb hat der PLATINUM SLS hier einen massiven quadratischen Querschnitt, der die Gesamtsteifigkeit effektiv erhöht - in beide Richtungen, seitlich und nach unten.

HINTERER BEREICH

Der hintere Bereich hat einen ähnlichen Einfluss auf die Gesamtsteifigkeit der Gabel wie der vordere Bereich, wobei der Einfluss zunimmt, je weiter man die Gabel verlängert. Im Gegensatz zum vorderen Teil, wo die Kräfte in mehrere Richtungen wirken, treten hinten 90% der Kräfte seitlich auf, da die Hauptkraft vom seitlich ziehenden Segel ausgeht. Da die Kräfte nur in eine Richtung wirken, ist die effektivste Geometrie hier ein asymmetrischer ovaler Querschnitt, der horizontal ausgerichtet ist.

GRIFF-BEREICH

Durch die drastische Erhöhung der Steifigkeit im vorderen und hinteren Bereich konnten wir den Außendurchmesser im Griffbereich um 1,5 mm verringern. Das hört sich vielleicht nicht nach viel an, aber in der Händen ist der Unterschied im Griffkomfort und der Ermüdung wie Tag und Nacht. Um den Griffkomfort weiter zu erhöhen und die Ermüdung zu verringern, haben wir auf der Innenseite einen "Bumper" angebracht.

Das Ergebnis? Durch die revolutionäre SEGMENTED CROSS-SECTION TECHNOLOGY erzielen wir eine Carbon Gabel, die einen neuen Maßstab in Punkto Steifigkeit UND Griffkomfort setzt.

Noch steifer und leichter als die Vorgängerversion mit reduziertem Durchmesser im Griffbereich, gibt es bis heute kein andere Gabel mit einem ähnlichen Durchmesser-Steifigkeits-Gewichts-Verhältnis wie die neue PLATINUM SLS!

Carbon bietet die höchste Steifigkeit aller Verbundfasern. Dies gewährleistet ein unübertroffenes Verhältnis von Steifigkeit zu Gewicht.

Leider hat Carbon aber auch die geringste Abriebfestigkeit aller Verbundfasern. Heutzutage sind alle Kopfstücke drehbar, wodurch das darunter liegende Carbon ständig "abgeschliffen" wird. Im Laufe der Zeit vergrößert sich dadurch das Spiel zwischen dem Kopfstück und dem Carbon-Korpus, was schließlich zu einem Bruch führen kann. Die grösste Schwachstelle jeder Carbon-Gabel ist daher der Bereich unterhalb des Kopfstücks.

Unsere Ingenieure haben eine einzigartige Lösung gefunden, um dies zu vermeiden, indem sie ein sehr ausgeklügeltes Lagerdesign eingebaut haben. Mit unserer TRIANGLE BEARING CONSTRUCTION bleibt die Carbonstruktur auch nach jahrelangem Einsatz vor Abrieb geschützt..

Ein Gabelbaum mit drehbarem Kopfstück benötigt seitliche "Anschläge", um zu verhindern, dass sich das Kopfstück seitwärts bewegt. Normalerweise werden diese seitlichen "Anschläge" zusammen mit dem Rest des Gabel-Korpus in "einem Schuss" gefertigt. Auf diese Weise wird jede Carbongabel hergestellt. Das Problem bei diesem Verfahren ist, dass die Carbonfasern in einem 90°-Winkel "gefaltet" werden, was eine potentielle Schwach-/Bruchstelle darstellt. Unsere Erfahrung aus der Vergangenheit hat gezeigt, dass die meisten Brüche genau an dieser Stelle auftreten.

Seit 2019 werden alle PLATINUM Gabeln in unserer einzigartigen 2 PHASE BODY PRODUCTION gefertigt. Das bedeutet, dass die seitlichen "Anschläge" in einem 2. Prozess an den Rest des Korpus angeformt werden, NACHDEM der Korpus fertiggestellt ist. Seitdem gibt es keine Brüche mehr in diesem Bereich.

Der Nachteil dieses Verfahrens ist, dass die Außenseite der "Anschläge" nicht perfekt glatt aussieht. Dies ist jedoch rein ästhetischer Natur und hat keinerlei strukturelle Auswirkungen.

Gebohrte Löcher zerstören die Carbonstruktur und sind daher weniger haltbar - zumindest theoretisch. Unsere Erfahrung auf dem Wasser hat jedoch gezeigt, dass es keinen Unterschied zu geformten Aussparungen gibt. Um eine geformte Aussparung zu erzeugen, müssen die Carbonfasern in einem 90°-Winkel "gefaltet" werden, was für die Struktur genauso schlecht ist wie ein gebohrtes Loch (siehe oben unter 2 PHASE BODY CONSTRUCTION).

Andererseits sind gebohrte Löcher schneller und billiger in der Herstellung. Dadurch können wir das Geld dort ausgeben, wo es wirklich einen Unterschied für die Haltbarkeit macht (z.B. siehe oben unter TRIANGLE BEARING CONSTRUCTION).

GABELBAUM GRUNDLAGEN

NEW-SCHOOL/WAVE BIEGEKURVE

Bei New-School Gabeln ist die Kurve auf die ersten 25-30 cm konzentriert, während der Rest des Gestänges gerade ist. Das bedeutet, dass du deine vordere Hand selbst bei kleineren (Wave-)Segeln nicht verdrehen/vertwisten musst, da sie sich immer noch innerhalb des geraden Teils befindet.

CLASSIC/RACE BIEGEKURVE

Klassisch geformte Gabelbäume haben eine weiter nach hinten reichende Kurve bis ca. 45 cm. Bei kleineren (Wave-)Segeln bedeutet dies, dass die vordere Hand verdreht/vertwistet wird, was zu erhöhter Ermüdung oder sogar Schmerzen im Handgelenk führt.Je größer das Segel jedoch ist, desto weiter wandert der Druckpunkt (und damit die Hände) nach hinten, so dass die vordere Hand nicht mehr verdreht ist.

Größere Segel haben auch ein tieferes Profil. Klassisch geformte Gabelbäume mit ihrer weiter nach hinten reichenden Kurve führen dazu, dass die Gabel in der Mitte breiter wird und das Segel den Holm nicht berührt.

Daher sind klassisch geformte Gabelbäume immer noch die erste Wahl für größere Freeride-/Slalomsegel (6,5 und aufwärts).

Carbon Gabelbäume sind 3 bis 5 Mal teurer als Aluminium Gabeln. Die Gründe für diesen drastischen Preisunterschied sind die massiven Unterschiede bei den Rohstoffpreisen und die Tatsache, dass ein Carbon Gabeln zu 100 % individuell/handgefertigt ist.

Da Carbon ein viel steiferes Rohmaterial als Aluminium ist, bieten Carbon-Gabeln 4 wesentliche Vorteile:

Wenn eine Böe auf Ihr Segel trifft, musst du kräftig dichtholen, um nicht die Kontrolle zu verlieren. Ein weicherer Gabelbaum biegt sich stärker durch, je stärker du ziehst. Diese seitliche Biegung führt dazu, dass die Gabel kürzer wird. Wenn der Gabelbaum kürzer wird, wird das Segel voller und sackiger = Verlust der Kontrolle.

Je länger der Gabelbaum ist (180 und höher), desto deutlicher wird der Unterschied in der Steifigkeit.

Carbon-Gabeln können viel leichter gebaut werden (bis zu 20 %) und bieten dennoch mindestens 20 % mehr Steifigkeit.

Mit Carbon kann man dünnere Durchmesser erzielen (bis zu 4 mm) und trotzdem eine mindestens 20 % höhere Steifigkeit erreichen. Generell gilt: Je dünner der Rohrdurchmesser, desto angenehmer ist der Griffkomfort. Das wird sehr deutlich, wenn man von einem dünnen Durchmesser zu einem dickeren zurückgeht.

Carbon verbiegt sich nicht. Daher hält eine Carbon Gabel in der Regel 3-4 mal so lange wie ein Aluminium-Gestänge, da jede Überlastung (Crash, Schleudersturz, ...) irgendwann zu einer verbogenen Gabel führt.

Da Carbon nicht korrodiert, erfordert eine Carbon Gabel auch viel weniger Pflege als eine Alu Gabel. Einfach den Zustand der Tampen von Zeit zu Zeit kontrollieren und im schlimmsten Fall mal den Griff austauschen, dann hält ein Carbon Gabelbaum jahrelang.

Je länger und/oder je ausgefahrener der Gabelbaum ist, desto weicher wird er normalerweise. Das Problem ist, dass je größer das Segel (= längerer Gabelbaum) wird, desto entscheidender wird die Steifigkeit des Gabelbaums für die Segelleistung und den Windbereich (siehe oben CARBON VS. ALUMINIUM).

Da man beim Beschleunigen, Pumpen oder wenn eine Böe auf das Segel trifft, mit der hinteren Hand zieht, ist der hintere Teil des Gabelbaums der wichtigste Teil für die Gesamtsteifigkeit der Gabel. Alle Gabelbäume sind heutzutage entweder mit einem innen- oder außenliegendem Endstück ausgestattet.

AUSSENLIEGENDES ENDSTÜCK

Erfunden vom DUOTONE-Team im Jahr 2007. Hier gleiten die Endrohre ÜBER den Gabel-Korpus.

Der größere Endstück-Durchmesser/Querschnitt erhöht die Gesamtsteifigkeit der Gabel um mindestens 30%. Außerdem wird die Steifigkeit der Gabel im Gegensatz zu innenliegenden Enden nicht beeinträchtigt, je mehr die Gabel verlängert wird.

Dennoch hat das aussenliegende Endstück 2 Einschränkungen:

a. Zum Verstellen der Gabellänge müssen die Verriegelungssysteme auf dem Endstück verschoben werden. Das macht die Bedienung weniger komfortabel und langsamer.

b. Bei einem üblichen Verstellbereich von 50 cm erfordert ein außenliegendes Endstück eine Mindestlänge von 180 cm. Bei einer kürzeren Länge kann es passieren, dass du mit der hinteren Hand auf dem (dicken) Endstück landest.

INNENLIEGENDES ENDSTÜCK

Dies ist die klassische Variante, um die Länge des Gabelbaums anzupassen, seitdem es verstellbare Gabeln gibt. Hier verläuft das Endstück INNERHALB des Gabel-Korpus.

Die Vorteile sind:

> Funktioniert mit jeder Gabel-Länge , da das Endstück nicht mit der hinteren Hand in Konflikt gerät.

> Das Verriegelungssystem für die Längeneinstellung ist fest mit dem Gabel-Korpus verbunden. Auf diese Weise lässt sich die Länge der Gabel einfacher, schneller und bequemer einstellen.

Der einzige Nachteil ist die geringere Steifigkeit, die umso größer ist, je mehr man die Gabel verlängert. Normalerweise ist der Winkel des Endstücks parallel zum Winkel des Gabel-Korpus (hinten). Auf diese Weise ist die Reibung zwischen den beiden Teilen am geringsten und das Endstück gleitet sehr leicht in den Gabel-Korpus. Das macht es sehr bequem, die Länge einzustellen, manchmal bis zu einem Punkt, an dem man ein gewisses "Klick-Klack" hört, wenn man stark an der Gabel "wackelt".

Die einzige Möglichkeit, die Steifigkeit eines Gabelbaums mit innenliegenden Endstück zu erhöhen, besteht darin, eine gewisse "Vorspannung" in der Gabel zu erzeugen. Dazu wird der Winkel des Endstücks so vergrößert, dass es nicht mehr mit dem Gabel-Korpus übereinstimmt. Durch diese Vorspannung wird zwar die Steifigkeit der Gabel erhöht, aber gleichzeitig der Komfort und die Bedienbarkeit bei der Längenverstellung deutlich reduziert (daher nur bei PLATINUM 170).

Unter normalen Bedingungen ja. Aber bei besonders starker Beanspruchung muss man zwischen Carbon- und Aluminium-Gabelbäumen unterscheiden..

Das schlimmste Szenario für einen Carbon-Gabelbaum ist ein Bruch bei massiver Überlastung. Carbon Gabeln biegen sich jedoch nicht. Daher können Carbon Gabeln auch im voll ausgefahrenen Zustand ohne Einschränkungen verwendet werden.

Aluminium hingegen kann sowohl brechen als auch verbiegen. Daher kann ein schwerer Fahrer und/oder eine Überlastung (z.B. Schleudersturz oder die Landung superhoher Sprünge) dazu führen, dass sich eine Alu Gabel im voll ausgefahrenen Zustand verbiegt. Als Richtlinie für wirklich schweren Miss/Gebrauch solltest du die letzten 15-20 cm der Gabel dann nicht benutzen.

TIPS & TRICKS

Du sollest immer vermeiden das Sonnencreme auf den EVA-Griff kommt. Nicht nur, dass Sonnencreme besonders die helleren EVA-Farben verunreinigen kann. Außerdem wird der Grip sehr rutschig, so dass man fester zupacken muss, was sehr anstrengend ist. Das Wichtigste ist jedoch, dass der Grip für immer rutschig wird, sobald Sonnencreme auf das EVA gelangt.

Es gibt 2 einfache Lösungen, um zu vermeiden, dass Sonnencreme auf den EVA-Grip gelangt:

Warte nach dem Auftragen der Sonnencreme, bis sie vollständig in deine Haut eingezogen ist, was mindestens 10-15 Minuten dauert. Da wir alle so schnell wie möglich auf's Wasser wollen, ist das allerdings nicht sehr praktisch.

Befreien deine Hände von der Sonnencreme entweder mit Alkohol (ziemlich unpraktisch) oder indem du deine Hände mit Sand "wäschst".

Bitte auch bei Lagerung oder Transport immer darauf achten, dass das Verschlusssystem der Längenverstellung geschlossen ist. In der geöffneten Position steht das Schnappteil unter voller Spannung und kann daher nach einiger Zeit etwas von seiner Schnappfunktion einbüßen.

Sogar Edelstahl- und Aluminiumteile werden mit der Zeit durch Salzwasser angegriffen.

Daher sollten man nach dem Urlaub im Salzwasser das Endstück entfernen und es zusammen mit dem Rest der Gabel mit Süßwasser abspülen.

Für die Überwinterung bitte das Endstück vom Gabel-Korpus entfernen.

Bitte überprüfe regelmäßig den Zustand der Tampen (Kopf- und Endstück). Mit der Zeit kann die Seiloberfläche durch die Klemmung in der Metallklampe beschädigt werden. Wenn der weiße Kern zu sehen ist, ist es an der Zeit, den Tampen zu ersetzen.

Der EVA-Griff ist sehr komfortabel für die Hände, aber er mag keine scharfen Gegenstände. Rigge daher nicht auf Beton auf, sondern versuche, auf weichem Untergrund (z.B. Sand oder Gras) aufzuriggen.

Kleine Schnitte im EVA solltest du einfach "ignorieren".

Kleine Teile, die sich ablösen, können leicht mit Sekundenkleber repariert werden.

Falls der Grip ersetzt werden muss (weil er grossflächig abgelöst ist oder weil du es nicht ertragen kannst, dass er die Schönheit deiner Gabel zerstört:-), versuche nicht, dies selbst zu tun. Dies ist eine sehr heikle und zeitaufwändige Prozedur, die du lieber Profis überlassen solltest.

Du benötigst Ersatzteile? Klick hier

Im Allgemeinen verwenden die meisten Leute hier nicht genug Spannung, was dazu führt, dass die Gabel bei hoher Belastung und/oder kabbligen Bedingungen langsam nach unten rutscht. Bei der Konstruktion des Frontstück-Hebels haben wir darauf geachtet, dass der Mast nicht brechen kann, wenn man das Kopfstück anschnappt.

Wir verwenden hier absichtlich einen eher "billigen" Polyester-Tampen. Im Vergleich zu Dyneema/Spectra-Seilen hat Polyester eine gewisse Elastizität. Diese geringe Dehnung puffert Belastungsspitzen (z.B. bei massiven Stürzen oder der Landung von hohen Sprüngen) ab und verhindert so eine Überlastung und einen möglichen Bruch der Kunststoffteile.

Das VTS TAIL Fitting ist nicht mit älteren Endstücken kompatibel. Ja, es hat den gleichen Endstückdurchmesser wie das iTail Wave Fitting (das iTail Race benötigt einen anderen/größeren Durchmesser). Aber der VTS TAIL-Beschlag wird mit ZWEI Schrauben (statt einer) am Endstück befestigt - und diese Schrauben befinden sich in einer anderen Position. Daher ist es nicht kompatibel.

Da sich aber die Dimensionen des Endstücks nicht geändert haben, kannst du ein komplettes Endstück einschließlich des VTS TAIL Fittings kaufen, um es mit einer iTail Wave Gabel zu verwenden.

WE DO CARE

Nachhaltigkeit ist die wichtigste und drängendste Herausforderung der heutigen Menschheit, um den kommenden Generationen eine lebenswerte Mutter Erde zu sichern!

In den letzten 50 Jahren hat sich Windsurfen zu einem Super-High-Tech-Sport entwickelt. Aber seien wir ehrlich, ungeachtet dessen, was andere euch erzählen mögen - mit Ausnahme von Aluminium-Gabeln und -Verlängerungen - sind Windsurfing-Rigg-Produkte eine "Mischung aus Kunststoffen auf Benzinbasis". Und in den misten Fällen sind bis zu 100% dieser Kunststoffe nicht recycelte (d.h. "frisch produzierte") Kunststoffe.

Zumindest bis heute gibt es keine umweltfreundlichen Ersatzstoffe für die strukturellen Komponenten, die die Mindestanforderungen für die Konstruktion moderner Windsurfing-Produkte erfüllen. Oder warum, glaubst du, will niemand mehr mit Holzgabeln, Aluminiummasten oder dehnbaren Stoff-Segeln surfen?

Es gibt nur einen nachhaltigen Ausweg aus diesem Dilemma:

LANGLEBIGERE PRODUKTE KREIEREN (LANGLEBIGKEIT = NACHHALTIGKEIT)

Ein Hochleistungsprodukt, das länger hält und im besten Fall sogar zusätzlich auf dem Gebrauchtmarkt eingesetzt werden kann, ist die beste und einzige Möglichkeit, die Ressourcen unserer Erde zu schonen.

Natürlich haben leichte Komponenten einen massiven Einfluss auf die Leistung und das Handling deines Riggs. Deshalb steht geringes Gewicht immer auf unserer Briefing-Liste, wenn wir neue Produkte entwerfen und konstruieren. Und DUOTONE-Produkte gehören zu den leichtesten oder in vielen Fällen sind die leichtesten auf dem Markt.

Aber Haltbarkeit und Langlebigkeit standen und stehen für uns immer ganz oben auf der Prioritätenliste. Unsere branchenführenden Garantieverlängerungen zeugen von dieser Philosophie:

- 2 Jahre bedingungslose Garantie auf fast jedes Hardware-Produkt (Masten, Gabeln und Verlängerungen+Bases).

- 5 Jahre Garantie auf 80% unserer Segel.

Bei Segeln können wir nicht genug betonen, dass insbesondere die Reduzierung der Dicke des Monofilms und des XPly-Laminats einen radikalen Einfluss auf die Langlebigkeit/Nachhaltigkeit hat. Eine Reduzierung der Foliendicke um 50% reduziert die UV-Stabilität um 70%. Nur um Magazintester oder Kunden kurzfristig zu beeindrucken, verwenden einige Marken bis zu 70% dünnere Laminate / Folien als wir. Dies entspricht nicht unserem Verständnis von Nachhaltigkeit.

IMMER MEHR

Da wir uns jedoch der Bedeutung der Nachhaltigkeit voll bewusst sind, können wir hier nicht einfach aufhören.

>> Nur wir haben aufgehört, Plastik für die Verpackung unserer Segel zu verwenden. Das spart ca. 5 qm Folie und Schaumstoff pro Segel.

>> Nur unsere Aluminiumprodukte (Gabelbäume und Verlängerungen+Bases) werden in einer CO2-neutralen Produktionsstätte hergestellt.

>> Nur unsere Aluminiumprodukte (Gabeln und Verlängerungen+Basen) werden zu 100% aus europäischen Rohstoffen in Deutschland hergestellt, um die Transportwege (zum Produktionsstandort und danach zu unserem Zentrallager) möglichst kurz zu halten.

>> Nur unsere Segeltaschen werden zu 100% aus recyceltem Kunststoff hergestellt.

>> Nur wir kompensieren alle Kohlenstoffemissionen, die durch unsere Segel während der Herstellung und des Transports entstehen, indem wir ein Wasserkraft-Klimaschutzprojekt in Sri Lanka, dem Land, in dem unsere Segel produziert werden, unterstützen.

WE DO LISTEN - BECOME PART OF THE DUOTONE DEVELOPMENT

DO YOU HAVE ANY INPUT OR IDEAS ON HOW TO IMPROVE OUR PRODUCTS?

SHARE YOUR THOUGHTS WITH US!

We strive to create products that are superior in performance and function to anything else on the market. Therefore, we are not just interested in the opinion and experience of professional riders, but listen to ALL windsurfers out there. Because we know we can learn from everyone, we want to collect the opinions of windsurfers worldwide.

This project runs throughout the whole year. Every year on January 15th, the best ideas will be rewarded and might actually be implemented into future products.

So, you have got an idea? Contact us >HERE< and take your chance to make a difference. (Please use "R&D input for DTW" as a subject line)

REWARDS

1st - One sail (free of choice)

2nd - One Silver Boom (free of choice)

3rd - One Power.XT 2.0 (free of choice)

Hast du Anmerkungen oder Fragen? Hier findest du Informationen aus erster Hand von R&D.

Je mehr Informationen du uns zur Verfügung stellst, desto spezifischer werden unsere Ratschläge und Hilfen sein. Bitte teile uns mit:

Dein Fähigkeitsniveau

Dein Körpergewicht und deine Größe

Kite-Modell(e) und Größe(n), die du benutzt

Bar und Leinenlänge, die du benutzt

Welche(s) Board(s) du verwendest

Bedingungen/Spots, an denen du kitest

Welche spezielle Frage hast du?

:grayscale(false):quality(10):blur(20))

:grayscale(false):quality(10):blur(20))